International Volvo Photo Locations Part 344

2022 – Volvo XC40, XC60 and XC90 (Europe versions) at Sutter-Stockton Garage on Stockton St in San Francisco, USA 🇺🇸

2017 – Volvo XC40, XC60 and XC90 (US versions) at Sutter-Stockton Garage on Stockton St in San Francisco, USA 🇺🇸

2017 – Volvo S90, V90, XC60 and XC90 T8 Twin Engine AWD Inscription in Crystal White Pearl on Sutter-Stockton Garage at 444 Stockton St, San Francisco, CA, USA 🇺🇸

2017 – Volvo S90, XC60 and XC90 T8 Twin Engine AWD Inscription in Crystal White Pearl on Sutter-Stockton Garage at 444 Stockton St, San Francisco, CA, USA 🇺🇸

2017 – Volvo V60, V90, XC60 and XC90 as German Spezialfahrzeuge on Sutter Stockton Garage in SF 🇺🇸

2022 – Volvo XC60 and XC90 Twin Engine on Sutter-Stockton Garage at 444 Stockton St, San Francisco, CA, USA 🇺🇸.

2022 – Volvo XC60 and XC90 Twin Engine on Sutter-Stockton Garage at 444 Stockton St, San Francisco, CA, USA 🇺🇸.

2018 – Sutter-Stockton Garage on Stockton St in San Francisco (Google Streetview)

2017 – Volvo XC40 at Exitlane of Sutter-Stockton Garage in SF USA 🇺🇸

2018 – Sutter-Stockton Garage on Stockton St in San Francisco (Google Streetview)

2018 – Sutter-Stockton Garage on Stockton St in San Francisco (Google Streetview)

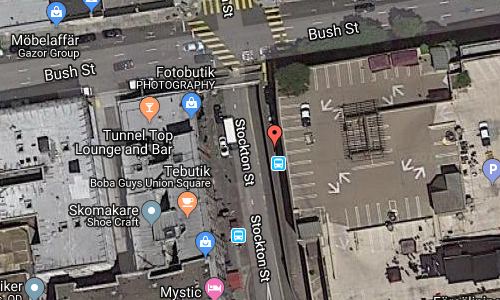

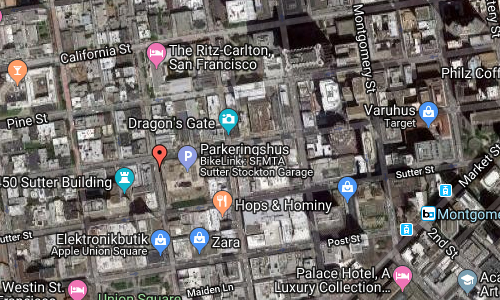

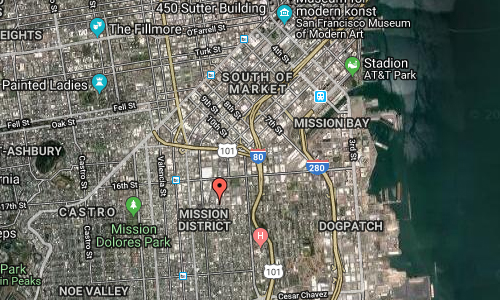

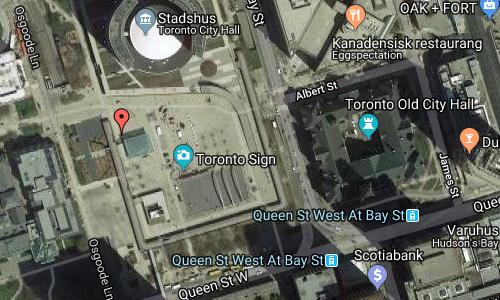

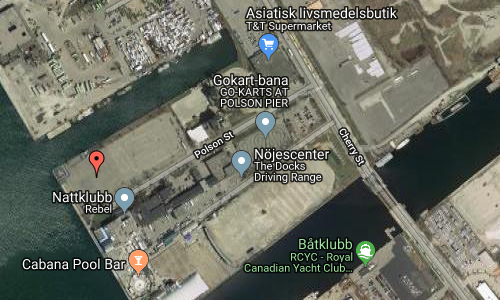

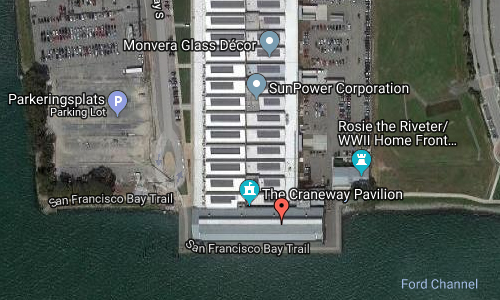

The Sutter-Stockton Garage is located on the Stockton St and Bush St in Downtown San Francisco, USA.

The exact location is the exit lane of the parking towards Bush Street.

This exit lane is just above the south portal of the Stockton Street Tunnel, a tunnel in San Francisco, California, and carries its namesake street underneath a section of Nob Hill near Chinatown for about three blocks. The south portal is located just shy of Bush Street, which is about two blocks to the north of Union Square. The north portal is located just to the south of the Sacramento Street intersection.

The tunnel was built to decrease the grade through the hill. Before the tunnel was built, the maximum grade along the route of Stockton north from its intersection with Sutter was 18% and the maximum grade south from the intersection with Sacramento was 12%. The tunnel was built with a maximum grade of 4.29% between Sacramento and Sutter. Initial plans in 1909 called for a tunnel 430 m long. The planned tunnel was shortened in 1910 to 230 m, with a width of 17 m and a height of 25 feet (7.6 m), with stairways connecting the tunnel with Pine and California streets.[4] The bore was narrowed slightly in 1912, with a total planned width of 42 feet (13 m) and a height of 18 feet (5.5 m).[8]

Construction involved lowering Stockton Street near where it passes into the tunnel from the South, evidence for which can still be seen at the building of 417 Stockton Street (Mystic Hotel), where the basement became the ground floor and the former front door is now a visibly marked window bay on the second floor.

More information at en.wikipedia.org and www.sfmta.com.

Thanks to Changyoung Jeong for finding this location!

Posts

Posts